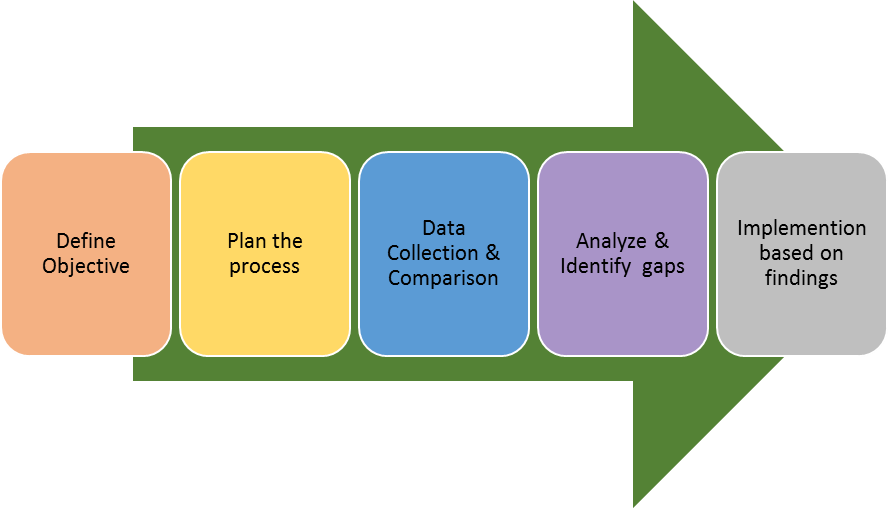

EVIQ believes that design & development of the right product requires research, better design, extraordinary analysis and proper implementation. We are capable of helping our customers design, develop, test and manufacture high-quality products with improved performance criteria.

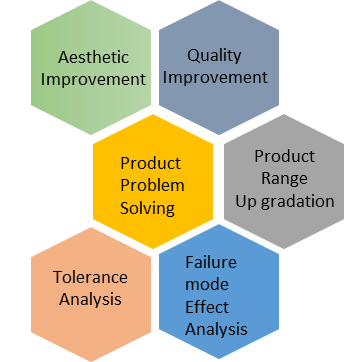

EVIQ offers the full spectrum of Engineering Design solutions from concept to completion. We provide specialist services like

- New Product development

- Design improvement

- Value Engineering

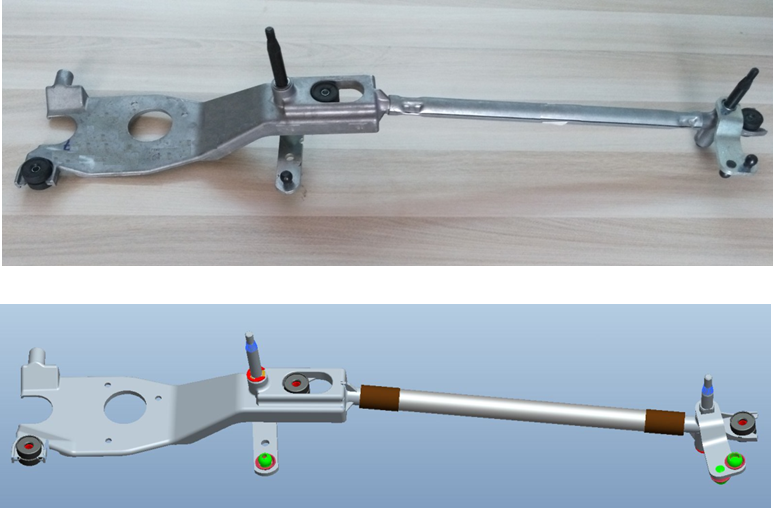

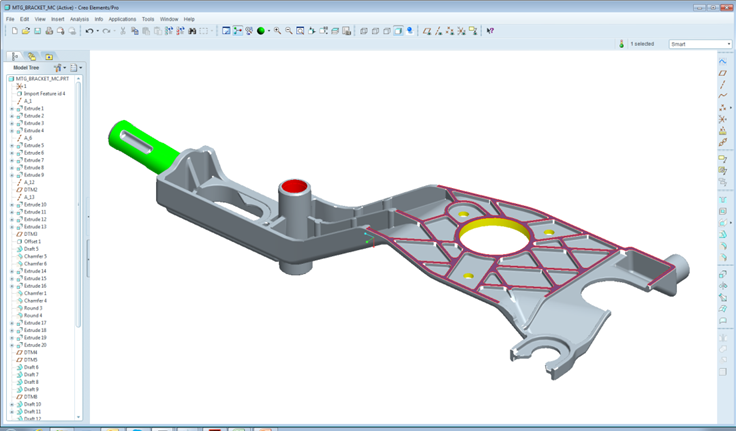

- Reverse Engineering

- 3D Modeling & Drafting

- Benchmarking

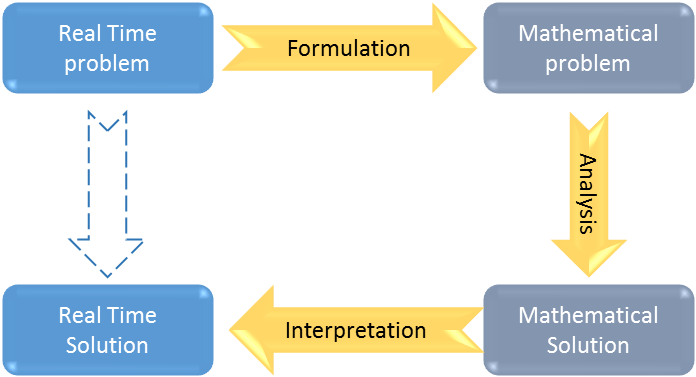

- Mathematical Model

- Industrial design

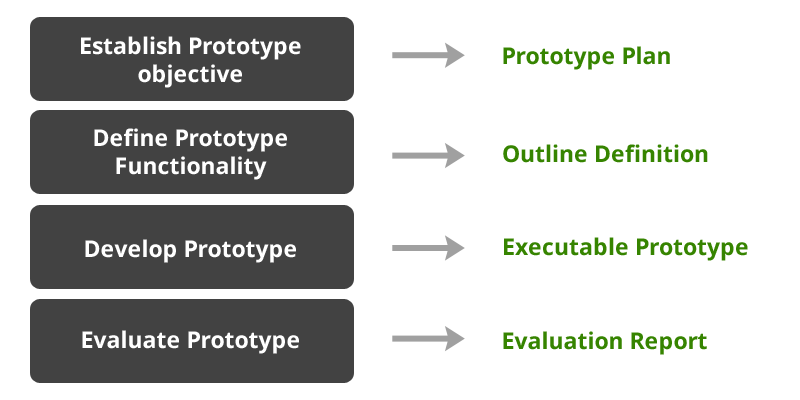

- Prototype Development

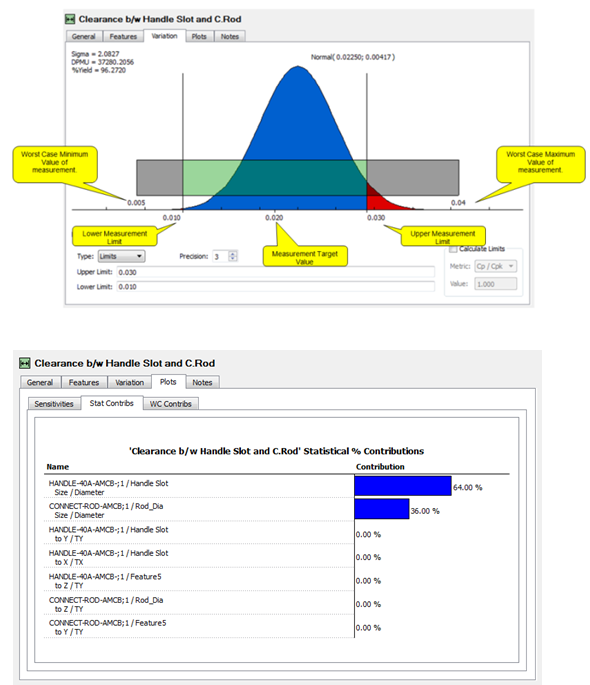

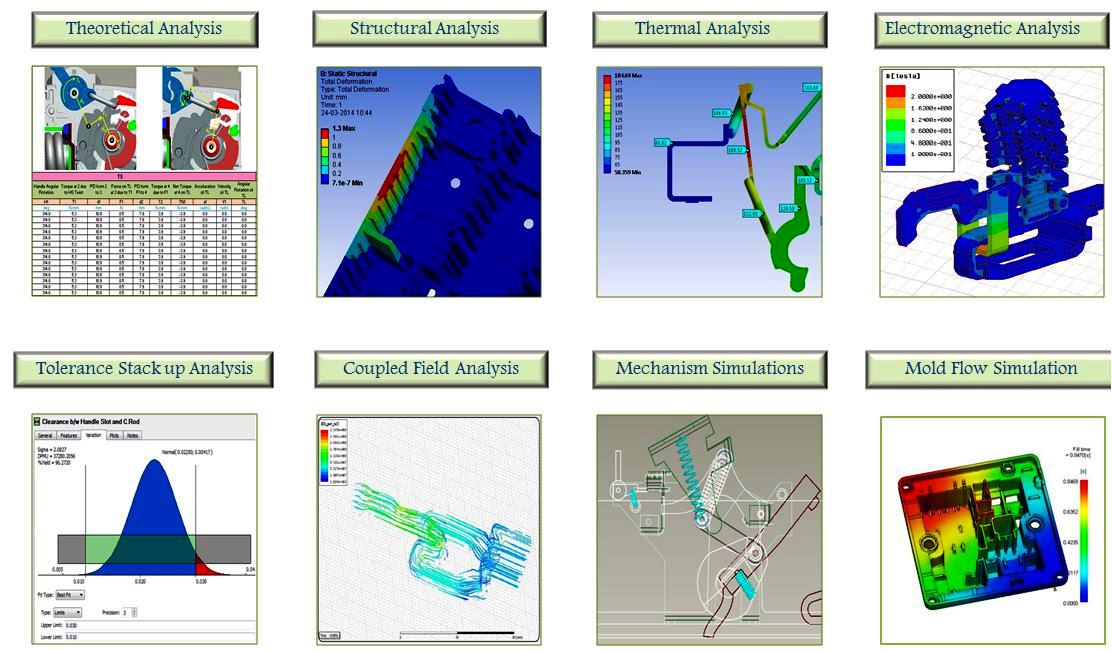

- Tolerance Stack Up

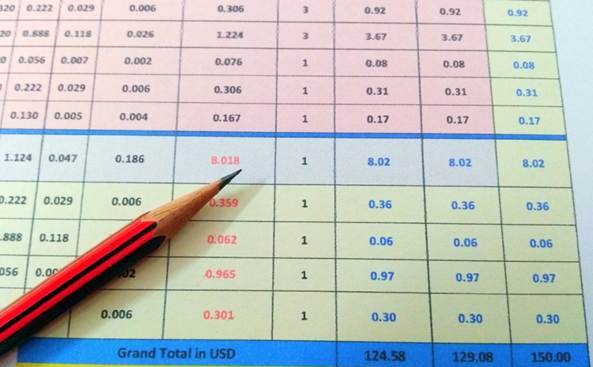

- Product Costing

- Simulation & Analysis